A selection of our recent news

Jan 2015 - Directional Drilling at the Nuclear Power Station that cannot be named......

January saw the completion of a project at a Nuclear Power Station, that unfortunately we're unable to list the name of, restricted you see! The largest installation involved a 162m x 160mm Directional Drill to as deep as 5m, through varying ground such as rock, clay, peat and many others. Other installations included 100m x Two Way 160mm, 108m x 160mm and a 50m x Five way (3 x 160mm, 2 x 125mm). The installations would have been complete within a week normally but working within a Nuclear site involves delays, restricted access, permits and procedures unlike any other site. SWDD realised this and factored it into the quote, expecting a two week installation time (which was correct). The client and the site operator were extremely pleased with our patience and understanding and said it will no doubt lead to future works. All installations were for 33kV and 11kV installations. |

|

Jan 2015 - Network Rail UTX's at Newton Aycliffe, installation 7 of 8

.jpg) |

Early January saw continuation of the HDD's (7 of 8) at the new Hitachi plant at Newton Aycliffe, working for Story, alongside Shepherds and Merchant Park Developments. SW Directional Drilling installed a 160m x 280mm UTX (Under track crossing) rising main installation that would later be adopted by Northumbrian Water. The installation had to alter due to some unknown piling under the bridge structure and was through very hard sandstone for 70% of the installation. Needless to say SWDD counteracted this and through perseverance managed to carry out the installation within four days. SWDD carried out all the design and Network Rail liaison, including all the calcs and Form's 1,2 and 3 for this project. Only one more installation to go! |

Dec 2014 - SW Directional Drilling complete 4 x 50m x Two way 110mm A120 Road crossings

Within a week in December SWDD installed another batch of 50m x Two Way 110mm crossings in the Colchester area for Vysionics. These installations were for a new variable speed camera network (someone's got to do it...) which is now in operation. The four installations we're complete in three working days but effectively took a week when factoring in utility sweeps, mobilisations and getting kitted up. The A120 area upgrade was ran by Jackson Civil Engineering, which was the first time SWDD had worked on a Jackson's site. Both clients we're very impressed with the SWDD "can do" attitude and no doubt there will be further works on the horizon. |

|

Oct 2014 - Network Rail crossings for HVMS in Stoke, 2 x 72m x 4 Way (2 x 160mm, 2 x 125mm)

|

Early summer SWDD were tasked to come up with a solution and design for a Network Rail crossing for 8 ducts in total as part of an electric upgrade. SWDD suggested breaking the installation down into two installations compromising 2 x 160mm and 2 x 125mm in one bore and the same configuration in another. This was suggested for a few reasons, mainly being: Settlement figures would be lower, the installations would be quicker, there would be less risk and smaller machinery could be used. These were all important as the site was restricted for space and with NR guidelines stipulating a minimum of a 4.3m crossing to meet their spec. SWDD suggested both crossings at 6m, with 5m separation. this method was accepted and the installations carried out in October. The works took only three days including mobilisations and utility checks. |

Aug-Sep 2014 - Start of the Hitachi/ Network Rail works at Newton Aycliffe (8 Rock installations)

April/ May 2014 - Heathrow Airport - 12 x 4 way 160mm - lengths of 100-250m - 6 weeks

Apr 2013 - Completion of 450m of 315mm drainage for Barratt Homes

| During the middle two weeks of April SW Directional Drilling completed a contract of approximately 450m of 315mm gravity drainage installations for Barratt Homes in Buckinhamshire. The installations were mainly in the range of 3-6m and would have been to quote "an open cut nightmare". There were some slight issues with the ground conditions not being clay as advertised (mainly rock) for 60% of the installation. The issues were overcome, as always and project was delivered on budget and on time. "So much for clay" were the words of the day, as you can see by the picture on the right. |

Feb 2013 - SW Directional Drilling complete 8 x M62 crossing installations, which totaled 20 ducts ranging from 125mm to 315mm in 10 days total.

After a tender process lasting about 2 years SW Directional Drilling were awarded the trenchless aspect of the Omega Phase 1 North project at Junction 8 on the M62. The final spec of the duct crossings to D Morgan and the Client were: 2 x 315mmm Gas Crossing, 2 x 315mm Drainage Crossings, 1 x 4 Way x 180mm Electric Duct Crossings and 3 x 4 way x 125mm electric/ Comms crossings. After a recent spell of very poor weather and a lot of rain SWDD mobilised to the busy (and very muddy) site to start their installations as required. SWDD had initially advised a 8-15 day installation time and got straight into it on the first day completing the first of the 4 Way x 125mm crossings. After some issues with some damaged plant SWDD managed to complete the installations on the Friday of the second week, 10 days in total and exactly to spec as the client had requested. All in all a good project and further works on this scheme are in the pipeline. |

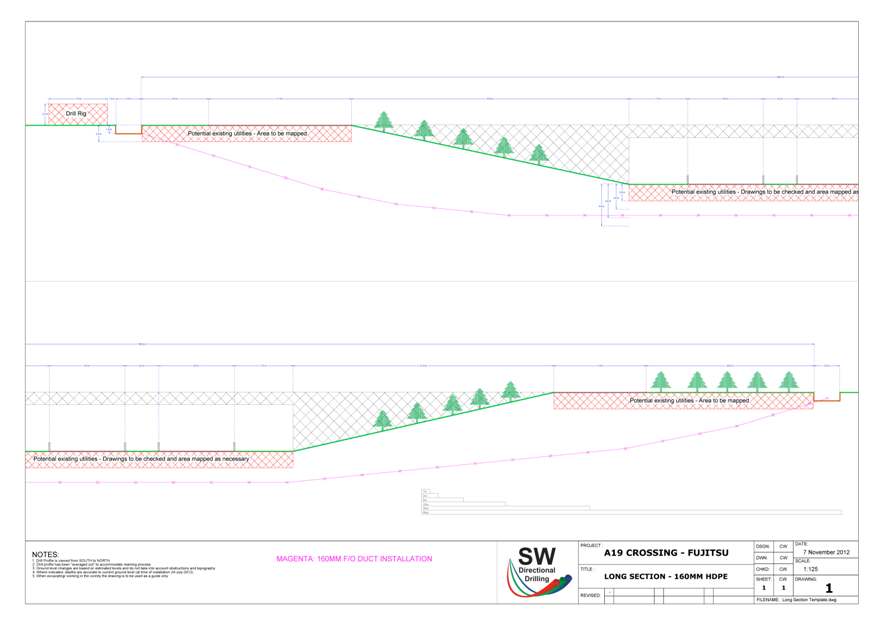

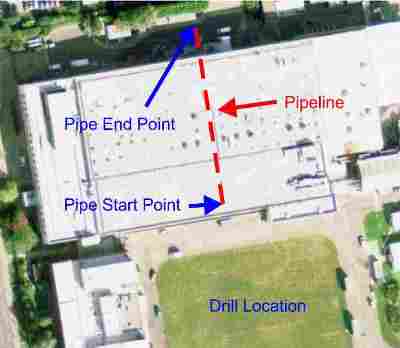

Nov 2012 - SW Directional Drilling complete Major A19 crossing for Fujitsu/ Virgin Media.

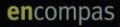

One of the main installations during autumn came about when Fujitsu Telecoms came to SW Directional Drilling SW Directional Drilling to find a solution to link a new mast with their current network. The closest existing network lied approximately 180m away on the opposite side of the A19, which is one of the main dual carriageway arteries of the North East. SWDD visited site with Fujitsu and the client Virgin Media, had a good look around the area and suggested an installation of 1 x 160m x 160mm HDPE duct to accommodate the telecom/ fiber optic cables as required. SWDD checked out the ground conditions with Clay and Sandstone dominating the GI and then sent calculations the the Highways Agency for approval, as usual there were no problems with the RAMS and calculations and the job was then booked in. A week later SWDD were on site with their "All Terrain" DitchWitch 3020 carrying out the pilot bore inside 5 hours and the pipe was installed 4 hours later, all works complete inside one shift. The bore plan/ As Built is available to view by clicking the image to the right. |

|

Aug 2012 - SW Directional Drilling complete 7 x dual 33kV circuit installations for MPE in Chessington.

|

Mid November SW Directional Drilling were contacted to provide trenchless solutions for the installation of two 33kV circuits and associated Fiber Optic ducting at 7 separate sites in the Chessington area. The works were part of a wider scheme to supply a new Digital Reality Data Centre and ducts installed were: 2 x 250mm, 2 x 125mm and associated 4 way F/O sub ducting for the 125mm ducts, with the works split over June, July and August. The Two installations at each of the 7 sites were complete within just 25 working days, with shots of 230m, 170m, 150m, 150m, 140m, 130m and 70m. The crossings included: Major Roads, rivers, culverts, wooded areas, sites of scientific interest, high pressure gas and fuel pipelines (numerous times) and various other obstacles. With varying ground conditions from London Clay to Ballast providing a varying challenge the installations were completed successfully and well within the estimated timescales given. |

Apr 2012 - SW Directional Drilling purchase the latest addition to the fleet, a New Ditch-Witch JT 4020.

| April saw SW Directional Drilling put pen to paper on purchase of a new DitchWitch JT 4020 Drill Rig. The New rig will offer the capability to drill bores up to 400m in a single installation and install pipelines up to 750mm diameter. With the added power the machine will save time on the upcoming projects that SWDD have lined up and provide more flexible installations to suit the ever evolving clients needs. The new machine offers 178 kN of thrust/pullback and 6800 Nm of torque, weighing in at 12,600 kg. | .jpg) |

Mar 2012 - SW Directional Drilling complete water installation at highly sensitive Stone Henge site for the new visitor's center due to be constructed.

.jpg) |

Mid May SW Directional Drilling provided a solution to IF Tech to supply and install Water pipe work to cross the major access road to Stone Henge. The supply was to feed a new visitors center which is due to be constructed alongside the A344. Excavation in this area was out of the question due to the archaeological impact and also to avoid heavy disruption to visitors to world famous site. SWDD mobilised to site and had the 50m x 180mm road crossing carried out through chalk, within 3 hours! All parties were very pleased with the installation and yet again the benefits trenchless methods far outweighed those of conventional trenching. Cost, time, disruption and productivity were key with this project and the trenchless method won on all 4 aspects. |

Feb 2012 - SW Directional Drilling offer full turn key solution to install 430m of 250mm SDR 11 Water pipe at the Stanlow Refinery, Ellesmere Port for ESSAR Oil (UK).

| Feb 2011 saw SW Directional Drilling take on a project to install 430m of 250mm SDR 11 water pipe to replace an existing main that was in a poor state. Once provided with required pipe diameter by the client, SWDD provided utility searches, design, route planning, liaison, installations, pressure testing, chlorination and connection all within 10 working days. Ground conditions were exceptionally soft clays as expected, providing potentially difficult steering for the highly powered machine. Nonetheless SWDD counteracted this by using a large blade drill and all installations went exactly as planned. Major utilities and drains were avoided along the route along the River Gowy and strict agreements with the EA had to me met, but these provided no problems for SWDD whatsoever. The client was ecstatic with the works and both parties look forward to working together in the near future. | .jpg) |

Jan 2012 - SW Directional Drilling complete 80m x 450mm "Rock Drilling" Surface Water drainage installation, crossing Rail/ A38 and Woodland for WBM Groundwork's and the Highways Agency.

.jpg) |

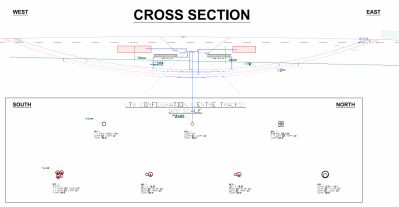

Early January SW Directional Drilling were challenged to come up with a solution to alleviate surface water collection/ flooding along a section of private railway. A 450mm pipeline had been suggested and the client requested an installation to reach the target. With all other methods impossible SWDD suggested a gradually curved installation to meet settlement requirements under tracks and also achieve the installation across the traffic heavy A38. The installation had to effectively run alongside the Rail line until sufficient depth was met then continuously steer left to cross the road at almost 90 degrees and meet the reception area. The installation went exactly as anticipated, although did provide a test for the "All Terrain" rock equipment. The works were complete inside 4 days much to the clients delight. With any other method this installation would have taken months, if it could have been completed at all. |

Oct 2011 - SW Directional Drilling complete two drainage installations of 42m x 355mm and 24m of 160mm at the new Barratt housing development at Chase Farm Drive, Blyth for Absolute Civil Engineering.

| October saw SW Directional Drilling complete 2 key drainage installations for Absolute Civil Engineering as part of a new Barratt Development. With SWDD's tender going in to ACE in 2010, this one took a long time to come to fruition. The main reason for delay was over 3rd party land ownership issues and the nature of the access road to be crossed being a busy route for ASDA deliveries. SWDD assisted to alleviate any concerns with regards to concerns with the road and come up with a solution for the installations. Initial investigations predicted boulder clay throughout which didn't initially cause much concern. Once on site though, ground conditions were found to be drastically different, solid sandstone, boulders and just about everything else. After consultations between SWDD and ACE we decided to use the rock equipment and alter the works slightly to accommodate this setup. With this equipment now in use the installations were achieved inside 3 days, much to the clients appreciation. | .jpg) |

Jun-Sep 2011 - SW Directional Drilling complete 20 crossings for fiber optic cables for North Midland Construction/ Thales

|

Over summer we at SW Directional Drilling completed 20 crossings of tram-lines, dual carriageways, roundabouts and other areas of a technically difficult nature as part of a major fiber optic contract for North Midland Construction/ Thales. Crossings were located in and around the Sheffield area and the ground conditions have been pretty difficult to say the least. Using an "All Terrain" rig on each job has ensured that all crossings have been completed successfully. The crossings have been through heavily congested utility areas, but due to our extreme professionalism and utility mapping all installations have been carried out safely and efficiently with minimum impact to the surrounding areas. |

Aug 2011 - SW Directional Drilling complete 4 no Single Way 250mm x 148m and 1 no 250mm x 192m Network Rail crossings for Birse Rail.

| August saw SW Directional Drilling complete 5 major crossings of the Network Rail Royston Mainline. Initially at tender stage this was designed by the main client as a four way Electric duct crossing and a single way Gas crossing. Upon arrival of the tender SWDD noticed this would massively exceed settlement tolerances stipulated by Network Rail. SWDD submitted an alternate design, which was accepted by NR and SWDD were awarded the contract. With Chalk ground conditions SWDD mobilised the "All Terrain" machine and the drilling works were completed in approx 15 days. |  |

Apr 2011 - SW Directional Drilling complete 100m x 6 way river crossing through the hardest ground imaginable!

|

April saw the completion of a major 6 way river crossing for Energetics. The crossing initially was due to be installed through limestone as local bore-hole information suggested but on arrival at site this was found not to be the case. Upon drilling the ground was found to be excessively tough and slow for Limestone and caused severe damage to tooling. Upon further analysis of the ground makeup, this particular area was found to be Basalt (one of the hardest rocks known to man) which is even harder than Granite! Once the correct ground makeup was established specialist tooling for the excessively tough ground was brought in which aided the task considerably. The installation compromised 3 x 180mm, 2 x 90mm and 1 x 125mm installations and was complete within 2 weeks drilling (after 2 other drilling companies had failed). |

24 Mar 2011 - SW Directional Drilling complete 80m x 225mm gravity effluent drainage run

below Glaxo-Smith-Kline production line.

| Today we at SW Directional Drilling completed some major drainage works through "predicted" solid sandstone for Interserve, with our new JT 3020 "All Terrain" Directional Drilling Rig. The pipeline to be installed was to exit from an almost impossible location deep within GSK's manufacturing building. Initially SWDD were contacted by Deveraux Architects to come up with a solution to a job that many deemed impossible. After assessing the job, timescales and ground conditions only 1 solution was possible, without excavating the production line at a cost of hundreds of thousands of pounds lost production per day. Directional Drilling was the solution and the project was complete within 2 weeks of drilling. The project was made complicated on site by running water from an unknown spring entering the bore and washing away vital drilling fluids, and a set back increasing from 30m to 100m! But after some consultation, the extensive list of obstacles were overcome and the pipeline was installed to spec. |  |

14 Feb 2011 - SW Directional Drilling confirm the purchase of a new AT 3020 Rock Drill

|

Today we at SW Directional Drilling completed the purchase of a new Ditch Witch 3020 All Terrain Directional Drill Rig, the only one in Europe, this further expands our broad capabilities and will be used on some of the major projects we have secured for the coming months. This new machine will enable simpler and more accurate installations through tough ground and Rock whilst increasing the accuracy of from +/- 1% to +/- 0.1%. This will enable us to further improve our already highly successful drainage installations. Where as with conventional equipment falls as tight as 1:100 could be achieved now we can install to tolerances of even 1:1000 in the most difficult of ground conditions, simply unbeatable by other methods. Another added bonus being the machine coming with a fully weather proof and heated air conditioned cab, keeping our drillers happy during the winter months! |

10 Feb 2011 - Completion of A1 Black Cat to Sandy Street Lighting Works

| On 10 Feb 2011 we at SW Directional Drilling completed a contract of approximately 40 Directionally Drilled crossings along the A1 between Black Cat Roundabout and Sandy in Bedfordshire. Crossings of main carriageway, slip roads and access roads as part of the major street lighting works were carried out over distances ranging from 17m-80m within minimum timescales in poor ground conditions. Working as a Sub contractor to DW Lighting/ Projects and under the joint venture of La Farge and Costain we carried out crossings of up to 4 way 110mm Electric ducts to accommodate the lighting cables for the new crash safe street lighting columns. All works were completed without incident and within 3 weeks to the great satisfaction of the client and main contractors. |  |

5 Feb 2011 - Completion of 180mm major gas supply to Glaxo-Smith-Kline manufacturing site at Barnard Castle

Today we at SW Directional Drilling completed a contract of approximately 200m of 180mm M/P Gas main to supply the GSK manufacturing site at Barnard Castle. Working as a sub contractor to Interserve we Directionally Drilled the main within 3 working days and provided the hot tap connection and pipe into the existing main and all associated excavations. Health and Safety was a critical part of this installation due to the nature of the chemical site and all works were carried out efficiently and expertly by our team to meet the Clients needs.

.jpg)